what are the three basic areas of a machine that require safeguarding

Dangerous moving parts in three basic areas require machine safeguarding. Dangerous moving parts in three basic areas require safeguarding.

Machine Safeguarding By Location And Distance

The types of waste include processes activities products or services that require time money or skills but do not create value for the customer.

. Machine Guarding Introduction. Power transmission apparatus which feeds energy to machines. The point of operation is the point where work is performed on the material such as cutting shaping boring or forming of stock.

The point of operation the power transmission device and the operating controls. Dangerous moving parts in three basic areas require safeguarding. There are several mechanical motions that pose risks to workers.

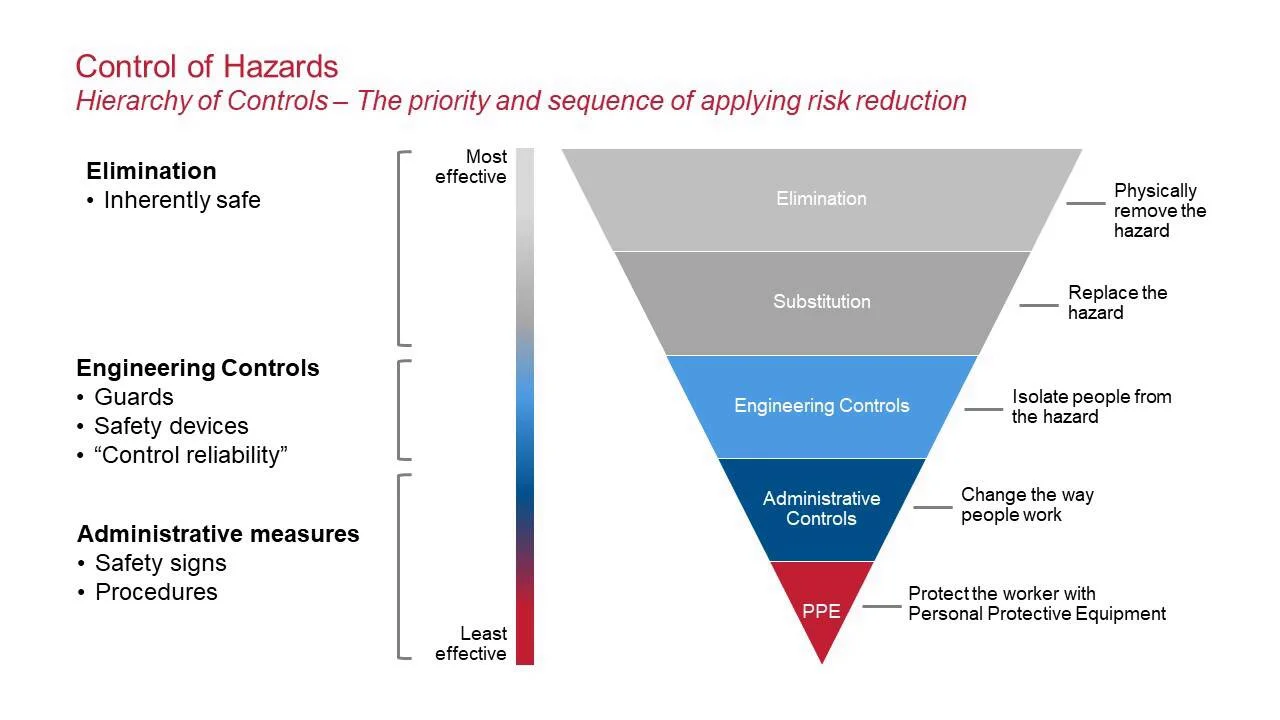

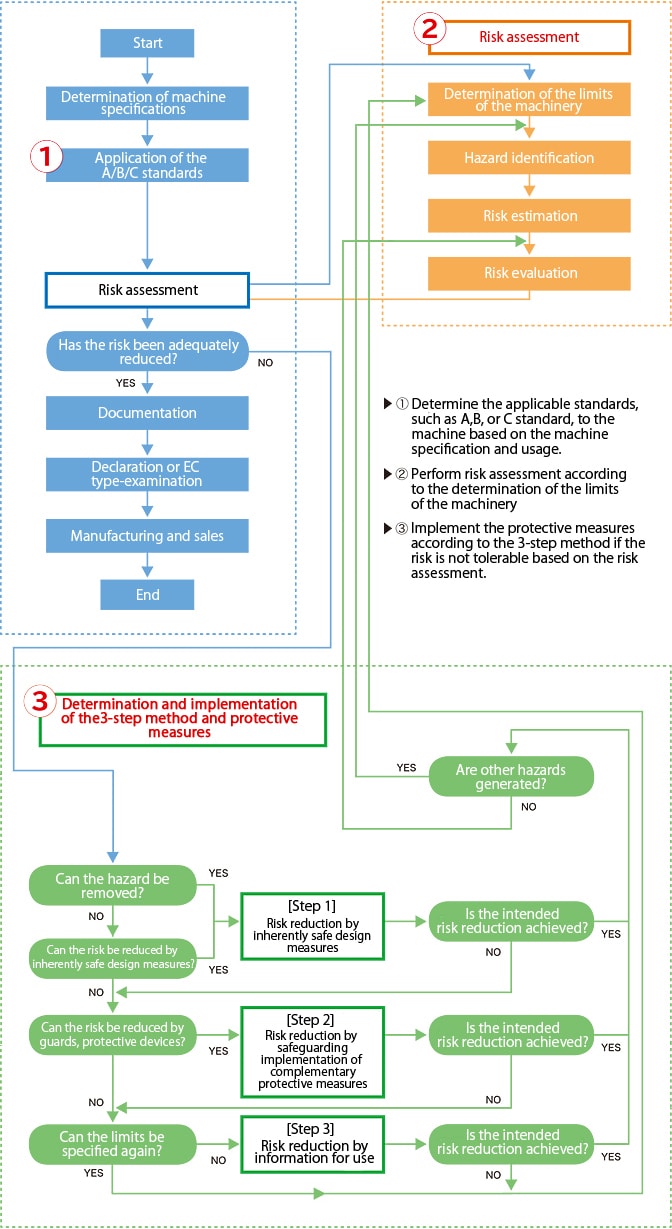

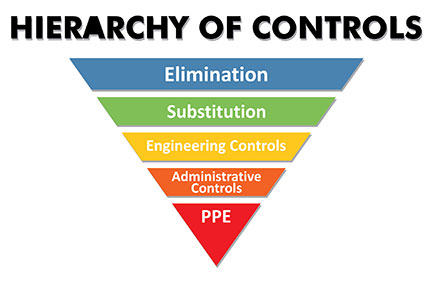

What are the three basic areas of a machine that require safeguarding. There are three permissible exceptions to the basic rule on patentability. Inherently safe design ie design-out the hazards Safeguarding and complementary protective measures.

The point where work is performed on the material such as cutting shaping boring or forming of stock. There are many ways to safeguard machinery. The point of operation.

All components of the mechanical system which transmit energy to the part of the machine performing the work. There are three common network security protocol standards. The point of operation.

All components of the mechanical system which transmit energy to the part of the machine performing the work. The point of operation. All components of the mechanical system which transmit energy to the part of the machine performing the work.

A machine machines require safeguarding wallpaper weight workout. Dangerous moving parts in three basic areas require machine safeguarding. All components of the mechanical system which transmit energy to the part of the machine performing the work.

All components of the mechanical system which transmit energy to the part of the machine performing the work. Dangerous moving parts in three basic areas require safeguarding. The point of operation.

OSHA states that mechanical hazards are most likely to occur in three major areas. The point of operation. The point of operation.

The point of operation from where all the work is performed. All components of the mechanical system which transmit energy to the part of the machine performing the work. Recent fatalities involving confined spaces demand that these areas be given more attention to reduce risk of injury or loss of life.

That point where work is performed on the material such as cutting shaping boring or forming of stock. The point of operation. All components of the mechanical system which transmit energy to the part of the machine performing the work.

Three basic area require machine safeguarding. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. The point of operation the power transmission device and the operating controls.

Which of the following is an example of a machine guarding hazard. The moving parts on a machine do not constitute a potential machine guarding hazard. In areas with expensive real estate such as Manhattan and urban Hong Kong this is a strong factor in favor of a tunnel.

Also know what are the most. Safeguarding There are many ways to safeguard machines. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards that occur during normal machine operation.

Basics of Machine. That point where work is performed on the material such as cutting shaping boring or forming of stock. The point of operation.

That point where work is performed on the material such as cutting shaping boring or forming of stock. Hanover Machine Tool Co. Three basic area require machine safeguarding.

Flying chips and sparks created by a machine. OSHA requires that machine hazardsmust be controlled or eliminated. Dangerous moving parts in three basic areas require machine safeguarding.

Moving parts which are part of the machine or bigger system. There are several mechanical motions that pose risks to workers. What are the three basic areas of a machine that require safeguarding.

That point where work is performed on the material such as cutting shaping boring or forming of stock. Machine safeguarding helps protect workers from preventable injuries in all three areas. All machines consist of three fundamental areas.

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require. Dangerous moving parts in three basic areas require safeguarding.

All components of the mechanical system which transmit energy to the part of the machine performing the work.

Cloudflare Completes Acquisition Of Area 1 Security In 2022 Security Network Security Areas

Machine Safeguarding By Location And Distance

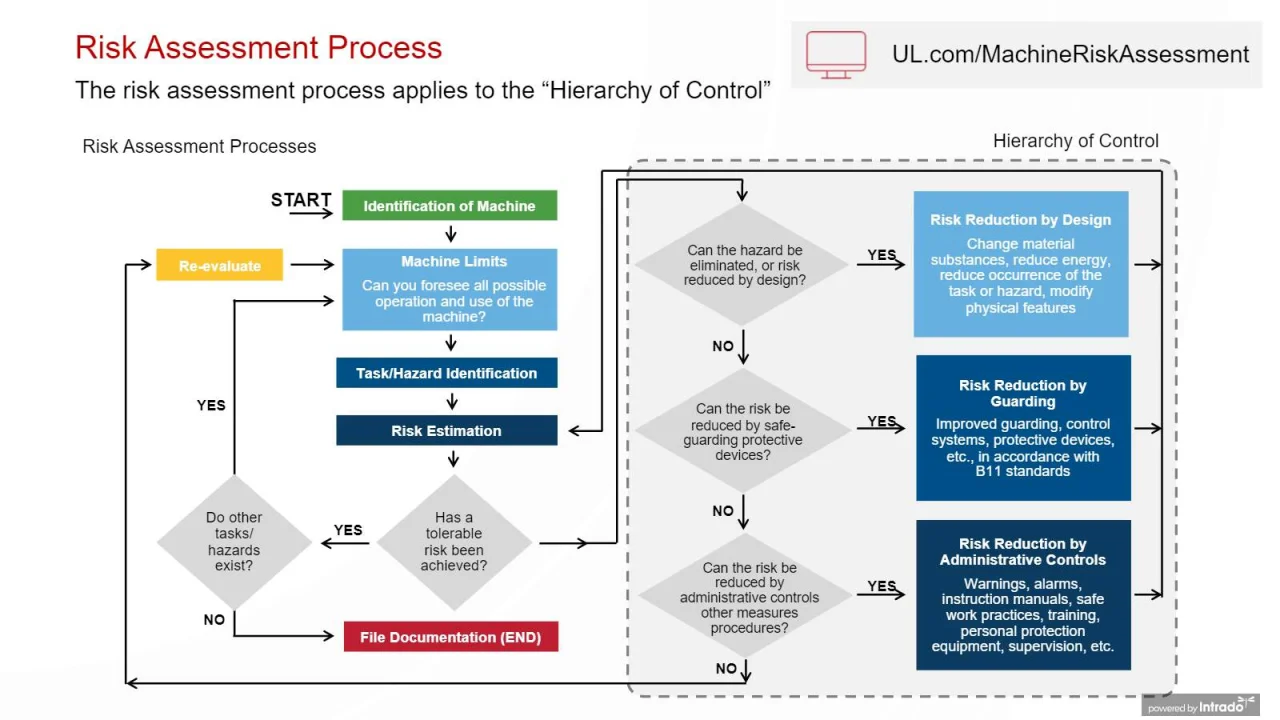

Essential Updates To Machine Safety Standards Ul

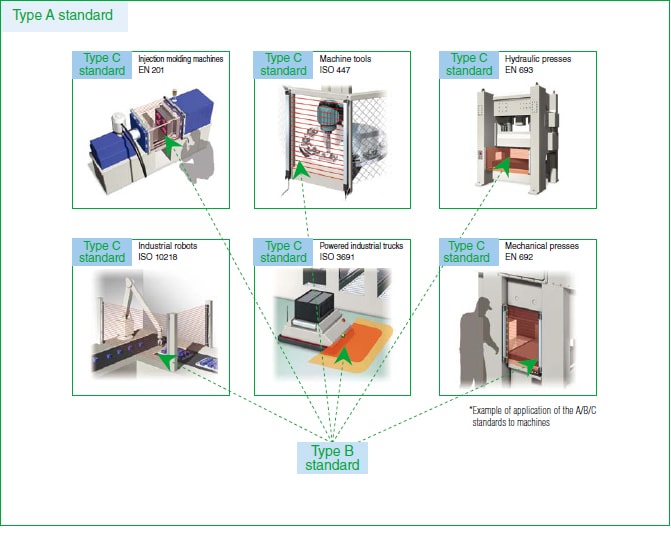

Machine Design Process Safety Knowledge Keyence International Belgium

Pin On Best 100 Kids Childrens Face Masks 2021

Machine Design Process Safety Knowledge Keyence International Belgium

Nca 1510 Empowering Soc As A Service With On Premises Security Gateway Security Solutions Network Security Empowerment

Basics Of Machine Guarding My Loss Control Services

The Azure Solution Architect Map Solution Architect Mind Map Map

Machine Guards Eliminate Hazards For Employees Article The United States Army

Harness The Power Of Dataanalytics Artificialintelligence And Bigdata To Find Untapped Value In Your Data Data Analytics Data Science Machine Learning

Fix Error Code 118 Steam In Windows 10 In 2022 Error Code Coding Error

Fix Failed To Initialize Battleye Service Generic Error In 2022 Error Popular Games Error Message

Basics Of Machine Guarding My Loss Control Services

Fix Set User Settings To Driver Failed In Windows 10 In 2022 User Settings Users Fails